can be determined with great accuracy.

Chemical variations can be influenced by the

weather, the day’s temperature, soil moisture,

age of plant, species variations, seasons, and

the region.

The primary bio-active ingredients for the

more popular manuka (of approximately 120

compounds) are referred to as triketones

(three oils: leptospermone, isoleptospermone,

and flavesone). The region which grows

manuka with most potent levels of this

triketone “chemotype” is around East Cape.

Kanuka, although not as directly bio-active,

imparts an important synergistic quality. It

has few of the heavy ‘tri’ oils, but contains

high levels of the ‘mono’ oil, the lighter

monokones. Its light nature allows it to be

more easily absorbed. Some producers

(such as

Earnhillfarm

of Kuaotunu) favour

the use of just one ‘pure’ oil. Others, like

NZ

Coromandel Mountains Tea Tree Oil,

prefer

to use a synergistic blend of the two. (See

following pages.)

MANUKA STUDIES CONTINUE

Manuka plantation studies are underway – for

both oil and honey uses – and researchers

acknowledge this “variability in essential

oil chemistry.” Not just species or region-

to-region differences, but variations in

one

manuka variety within

a single growing plot.

This illustrates just how complex it is to find

the

perfect tree – that powerful ‘elite line’

and best ‘regional ecocrop’ – for commercial

scale honey production or oil extraction.

Studies will continue for years perhaps, but

are promising enough for a government

report! The government estimates that

exports of manuka honey alone will top

$1 billion per year by 2025, with additional

value coming from the managed-forest sale

of branches for oil extraction. Even ‘carbon

credits’ and farm subsidies are part of the

profit picture! For this reason, paddocks are

now actually being planted with manuka for

honey production.

(See brief of strategy here:

www.kauriparknurseries. co.nz/manuka-1b-industry-2025/)Studies like this were previously carried

out by the Aussies to isolate tea tree plant

varieties with high levels of terminen-4-ol (the

oil’s primary active ingredient). They had a

history of plantation oil production going back

to the 1920s, and the 1960s saw an upswing

in essential oil use paralleling the public’s

growing interest in natural healing.

In 1982, the late Peter Molan of the University

of Waikato discovered the “exceptional type

of antibacterial activity bioactivity of our

manuka honey”, and interest in these oils and

honey has grown ever since. You may now

start to see kanuka honey for sale as well.

The plantation level production guide (noted

above) recommends periodic herbicide

spraying to keep down weeds. But smaller

private New Zealand oil producers can boast

‘organic’, ‘wild grown’ and ‘hand harvested’

to appeal to the discerning health-conscious

consumer. They often own the land their trees

M

anuka and

K

anuka

are on, so can guarantee that

the branches, blossoms, and

land have not been sprayed.

Some producers also have

their distilled oils lab tested

for active ingredient content.

(Manuka honey has several

rating systems to indicate its

medicinal strength.)

USES OF ESSENTIAL OILS:

MEDICINAL AND AROMATHERAPY

These essential oils fall into two use

classifications: for aromatherapy and to

directly treat conditions such as bacterial/

fungal infections, acne, cuts, boils,

inflammation, and sinusitis (the oils are

breathed in by steam).

It is suggested that for skin application, these

strong essential oils be diluted with a carrier

oil (add a few drops to the oil you plan to use)

as the essential oils may be too drying and

irritating used ‘neat’ or straight.

Some oils may be toxic when used internally,

but dilute forms for mouthwashes or herbal tea

blends should be safe.

Aromatherapy is based on the effect of

oil vapors on smell and emotion. Manuka

and lavender are relaxing

,

while others

like rosemary or peppermint are mentally

stimulating. The oils might be gently heated,

perhaps in a candle or heating element; drops

might be added to room sprays, mixed with

soaps, and added to lotions or massage oils.

And, of course, perfumes.

– Carol Wright

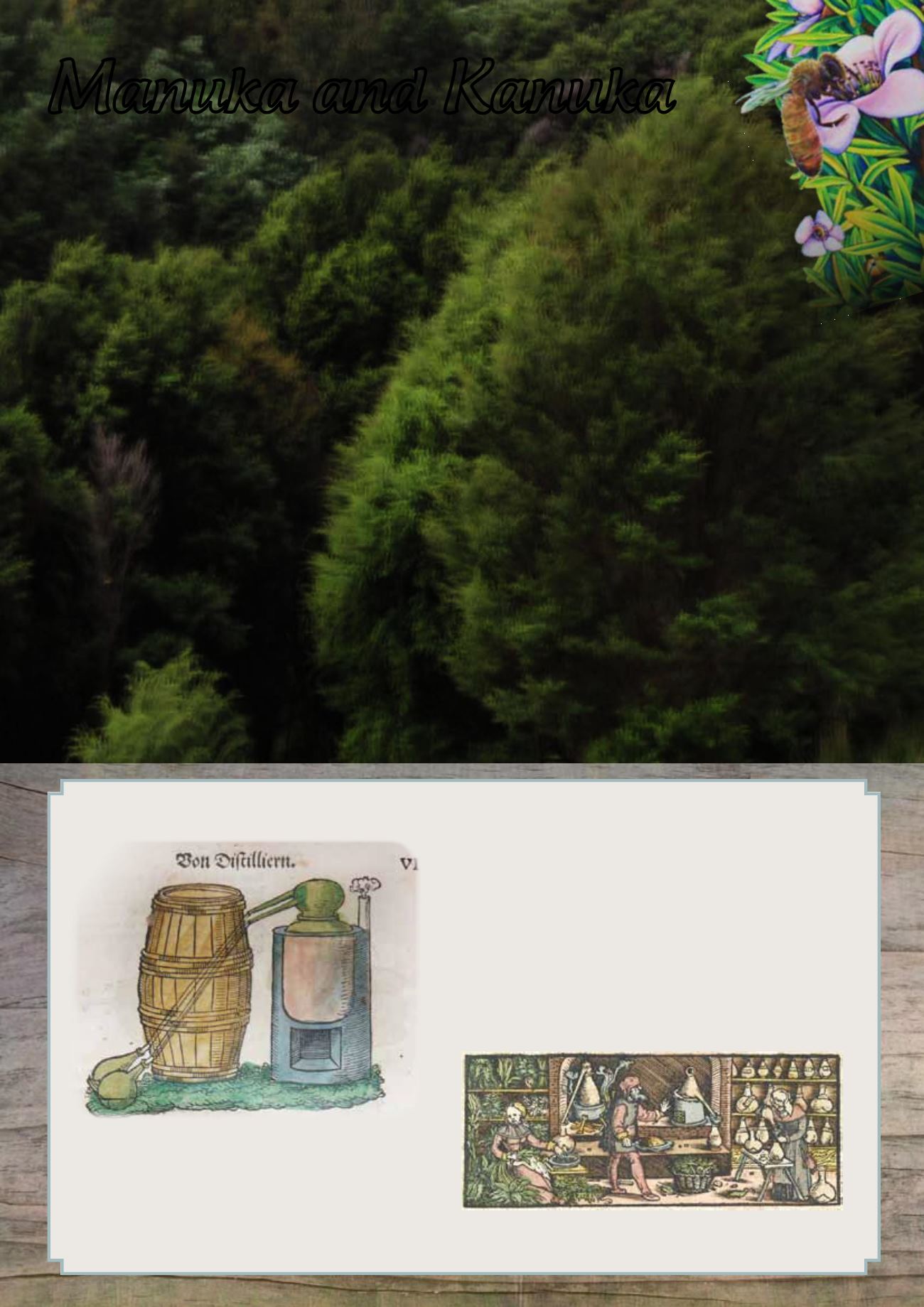

This woodcut from the mid-16th century depicts the process of distilling

essential oils from plants with a conical condenser.

Via the Wellcome Library, London

Illustration from the 1557 German Renaissance

Adam Lonicer’s “Kreuterbuch” (literally “herb book”)

See

www. christstreasures.blogspot.com/2013_05_01_archive.html WWW.COROMANDELLIFE.CO.NZ23

Read about many other oil extraction methods here:

www.naha.org/explore-aromatherapy/about-aromatherapy/how-are-essential-oils-extracted/The basics of steam distilling oils have not changed much over the

centuries. Plant materials are placed in a container and hot steam

rises through the bundle dissolving the oils. The steam is cooled and

condensed by water in the barrel (as shown above). The oily liquid is

then collected, and the floating oil siphoned off.

DISTILLING...

THE MORE IT STAYS THE SAME

As far back as 3000BC, the Egyptians used aromatic plants for medicinal and

cosmetic purposes, as well as for the embalming of the deceased.

In 900AD, Avicenna, famous child prodigy and physician from Persia, wrote

many documents describing 800 plants and their effects on the body. Although

sometimes credited with the development of the distillation process for

essential oils, it is more probable that he greatly refined it, for archaeologists

have found primitive distillers that date from before his lifetime.

Today distillation is still the most common process of extracting essential oils

from plants. The advantage of distillation is that the volatile components can

be distilled at temperatures lower than the boiling points of their individual

constituents and are easily separated from the condensed water.

Of course, more valuable than leaf or herb sourced oils are those from flower

petals and blossoms for use in perfumes. These more fragile materials demand

gentler or non-heated extraction processes.